Posted January 15 2022

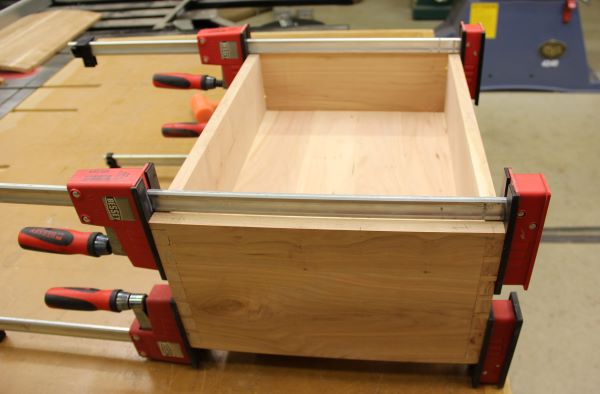

The chest case is made from 4 sides connected together with hand-cut dovetails, tail boards in the front and back. Before glue-up, all 4 sides receive a horizontal dado on the inside for the top compartment bottom to float in. The front and back pieces receive a vertical dado to install the 2 drawer side-slides into after glue-up. The front piece is also cutout for the opening to the drawer compartment.

After glue-up, the 2 drawer side slides are glued in place. Spacers are added to the side of these to get the compartment exact for the drawer width. The stand will receive a top that will also double as the chest bottom for the drawer to slide on.

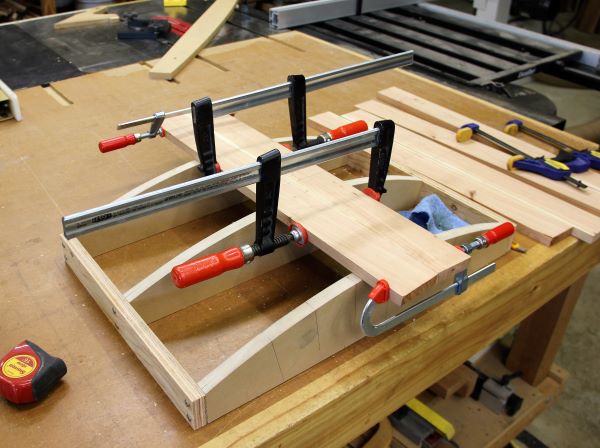

To start the coopered top, the first order of business is to construct a pattern of the desired arc that is large enough to hold the individual boards for glue-up. These boards have the side angled on the jointer to the approximate bevel of the arc. Fine tuning of the bevels is done with hand planes. Instead of gluing all the boards at once, I glue them in pairs and then put all the pairs together for final glue-up.

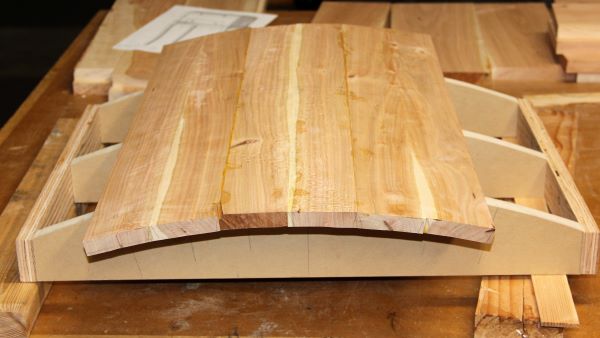

After cleaning the glued-up top with hand planes and spoke-shaves, boards for the 2 top ends need to be selected that match the grain and color of both the top and the chest sides. The height of these boards will also determine the height of the top off the chest.

The top is trimmed on the table saw to the width of the chest plus a small amount extra for fine tuning. The front and back vertical pieces are glued to the edges of the top. These are oversize in all directions to allow for fine tuning with hand planes and hand saws.

The end pieces are roughed into place, the oversize allowing fine tuning in all directions, especially on getting the critical arc fit perfect. The ends are glued in place and then cut to fit the height of the front and back pieces. The entire top can now be smoothed by hand-plane to the final dimensions.

The drawer is also a hand cut-dovetailed box with a bottom. It will slide on the top of the stand and must be fitted accordingly. The stand top is first attached to the underside of the chest case, and then the entire assembly is attached to the stand with standard top clips to allow for seasonal wood movement. Knobs were made on my lathe from some scraps of Gabon Ebony.

The cabinet is finished with several coats of a wipe-on/brush-on polyurethane (General Finishes), sanding with 400 grit paper between coats. Butt hinges from Brusso are used to attach the top. The cherry really shines after gaining that patina that makes it so wonderful for woodworkers.

Back To Top Home